FERO Corporation

FERO Corporation is a leading engineering, manufacturer, and global supplier of superior masonry construction technologies. For over 25 years, we have been providing masonry reinforcement systems and solutions for the global construction industry, meeting or exceeding established standards councils’ specifications on our engineered masonry products and services.

We maintain a deep-rooted approach to reducing cost, reducing material requirements and simplifying the application process of our products. Some of our products require only one trade to apply. Many of our connectors, anchors and ties are original patents that have been tested in complete assemblies in our facilities.

When you choose a FERO Engineered Construction Technology you have the knowledge that all systems have been tested, certified and proven in the field to perform as specified.

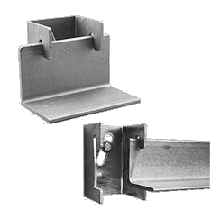

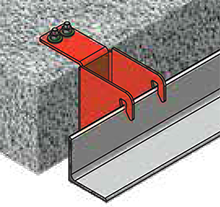

Shelf Angle Support - FAST

Our FAST™ System is a unique approach to shelf angle installations.

The FAST™ (FERO Angle Support Technology) system was devised to meet a demand for building technology that offers fast, low-cost, and effective shelf angle installations.

The FAST™ system eliminates the need for welded connections, and therefore:

• Can be installed by one trade

• Requires less time to install

• Ensures integral corrosion protection

• Lowers overall costs

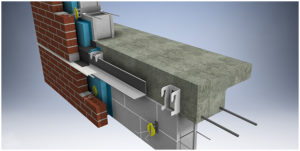

The system is designed to offset the shelf angle from the structural backing, and to allow cavity insulation and the air/vapour barrier (AVB) to be continuous behind the steel shelf angle, which:

• Dramatically reduces thermal bridging

• Reduces the number of penetrations through the insulation

• Minimizes joints/junctions in the AVB

• Reduces shelf angle crosssection and material cost

• Reduces insulation and AVB installation time

The FAST™ system consists of a FAST™ bracket, anchor bolt, (optional) Shim Plates and Wedge Shims. .

FAST Standard

With the FAST system, the size of the shelf angle remains the same, and the supporting brackets vary in size to accommodate a wide range of design cavity widths. The FAST system uses a 100 x 100 x 6 mm (4″ x 4″ x 1/4″) angle which is readily available and less expensive than using larger non-standard angles. Installation of the system is simple. A chalk line is snapped to establish the location of the brackets in elevation, and anchor holes are pre-drilled at the required spacing.

One of two methods may be used to position and fasten the brackets:

Method 1. Accurately position the shelf angle temporarily or by installing brackets at its outer ends. Hook the intermediate brackets onto the angle and spread them horizontally to their bolt locations. Securely fasten the brackets against the structural backing. or:

Method 2. Accurately position the brackets at each anchor location, both in elevation and perpendicular to the wall. Securely fasten the brackets against the structural backing. Rotate the angle into the claws of the brackets.

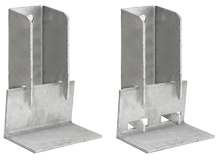

FAST Inverted Shelf Angle Support

The FAST™ System also includes a Inverted Shelf Angle Support (Type II) for applications requiring a flush shelf support. FERO FAST™ Bracket Type II uses the same 100 x 100 x 6 mm (4 x 4 x 1/4 in) steel angle, shim plates and spacers as the original standard bracket.

The FAST™ bracket Type II offers the same great advantages:

• Takes less time than other angle support methods

• Allow flush mounting at the top of the foundation

• Can be installed by one trade

FAST Lintel Shelf Angle Support

The FAST™ Lintel is a unique approach to shelf angle installations over wall openings. The FAST™ (FERO Angle Support Technology) system now also offers a lintel shelf angle to support masonry veneer above window/door openings. With the ease of installation of our FAST™ system, the use of FAST™ Lintel creates a clean reveal on the underside of openings making them ready to receive window or door framing without any treatment.

The FAST™ Lintel offers the same great advantages of FERO’s Angle Support Technology and:

• Takes less time than other angle support methods

• Eases door and window installations

• Can be installed by one trade

FAST Extended Shelf Bracket

The FAST™ Extended Bracket has been engineered to the same high standards as the original FAST™ Bracket and allows the angle to support veneers below the floor level where this option is desirable. The FAST Extended Shelf Bracket is a completely customized bracket that can be manufactured to satisfy your building specifications. FERO FAST™ Extended Bracket can be used with either the standard 100 x 100 x 6 mm (4 x 4 x 1/4 in) steel angle, shim plates and spacers as the original bracket or can be specified to accommodate the modified FAST™ Lintel 150 x 100 x 8 mm (6 x 4 x 5/16 in) shelf angle.

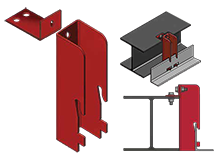

FAST I-Beam Brackets

FAST I-Beam Shelf Brackets are designed for buildings constructed with steel columns and beams that require shelf angles to support the cladding. All FAST I-Beam Shelf Brackets have been engineered to the same high standards as the original FAST Bracket and allows the angle to support veneers from an I-Beam where this option is desirable. These I-Beam Shelf Brackets can be customized to align with the bottom, middle, top or above the I-Beam while maintaining the same wall design specifications.

FAST HAB (Hold Above Beam) I-Beam Shelf Brackets supports the veneer above the I-Beam, either flush or 3 inches above the beam

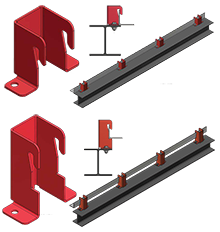

TOS FAST Brackets

TOS FAST Brackets are used when it is desirable to support the veneer from the top of a thin slab. FERO FAST™ TOS Bracket can be used with a standard 102 x 102 x 6.4 mm (4 x 4 x 1/4 in) shelf angle.

Masonry Connectors & Ties

For Concrete Block

Block Shear Connector

DESIGNED FOR COMPOSITE STRUCTURAL ACTION – A SHEAR TRUSS

Block Shear™Connectors allows cavity walls to behave uniformly, resisting vertical shear by “connecting” the exterior masonry veneer to the concrete block backing. The entire wall functions like a truss, with both wythes performing uniformly as tension and compression components of the truss. This enables structures to withstand more load with thinner walls, less reinforcement material, and less material costs.

Slotted Block Tie Type I

Slotted Block Tie (Type I) affixes masonry veneer walls to a structural backing like concrete block masonry. Designed to Transfer Lateral Loads While Accommodating Construction Tolerances.

Slotted Block Tie Type II

The Slotted Block Tie (Type II) system consists of a double-Slotted Block Plate, when compared to the Slotted Block Tie (Type I), which uses a single slot rather than two shorter slots, the Slotted Block Tie (Type II) offers greater vertical adjustability, reduced displacement, and higher strength.

Heavy Duty Holed Rap Tie

Heavy Duty Holed Rap Tie affixes masonry veneer walls to a structural backing either directly, or by surface mounting to any sheathing sitting over a stud. The functionality of the Heavy Duty Holed Rap Tie is to transfer lateral load from the exterior masonry veneer to the structural backing with the use of one fastener. By using multiple fasteners, both shear and axial forces can be resisted, and this enables the entire wall assembly to function as a whole. The wall thickness (including the veneer and structural backing) work to limit lateral load, offering reduced lateral deflections and increased resistance.

For Insulated Forms

ICF Connector (Insulated Concrete Form)

Our ICF Connector system assembles a masonry veneer over an insulated concrete form backing. The Slotted ICF Connector Plate is embedded directly into the ICF. This creates a stable integration and it reduces any play, deflection or connector deterioration.

For Metal Stud

Stud Shear Connector

Designed to Transfer Composite Loads When Using Light Frame Structural Walls.

Our Stud Shear™Connector is an especially innovative product for trades using a light frame as a structural backing for an assembly. The orientation of the connectors to the studs provide an unmatched rigidity as it eliminates axial and vertical shear through the tie mechanism. The entire assembly becomes the resistant variable in the construction, rather than all of the resistance being forced upon the studs alone.

Slotted Stud Tie Type I

Our Slotted Stud Tie system transfers lateral load from the tie through a plate, which transfers the load to the stud backing. As the plate is directly fastened to the stud, all load is transferred efficiently.

Slotted Stud Type II

When compared to the Type I Slotted Stud Tie, Type II provides increased adjustment, flexibility in assembly and increased strength.

Type II Slotted Stud Ties are best utilized in steel wall assemblies where the demands of vertical movement between the veneer and the structural backing are high, like in cases of high walls or multi-storey structures with full-height veneers.

Side Mounting Rap Tie

Designed to Transfer Tensile and Lateral Loads.

Our Side Mounting Rap (Rod Adjustable Plate) Tie affixes masonry veneer walls directly to a structural backing stud without any intervening materials (like sheathing).

Slotted Side Mounting Rap Tie

Our Slotted Side Mounting Rap Tie provides a constant connection of the veneer wall to the structural backing without any risk of veneer disengagement. The vertical functionality of the Slotted Side Mounting Rap Tie enables it to resist tensile and compressive lateral loads, and its ability to unify the entire wall assembly to work as one singular component may reduce the need for reinforcement, additional wall thickness or materials.

Holed Rap Tie

Designed to Transfer Lateral Loads to Light Structural Walls With or Without Sheathing or Concrete Back-Up Walls. Our Holed Rap Tie affixes masonry veneer walls to a structural backing either directly, or by surface mounting to any sheathing sitting over a stud.

Slotted Rap Tie

Our Slotted Rap (Rod Adjustable Plate) Tie affixes masonry veneer walls to a structural backing stud either directly, or by surface mounting to any sheathing sitting over the stud. Our Slotted Rap Tie transfers tensile and compressive lateral loads to the stud backing.

For Wood Studs

Slotted Rap Tie

Our Slotted Rap Tie transfers tensile and compressive lateral loads to the stud backing. The L-shaped Plate is fastened to the facing surface of the structural backing, which may be steel, wood, or miscellaneous metal.

The V-Tie is inserted into the slot and allows 2 inches of vertical play to align with the grout bed. After set-up the V-Tie providing a constant connection of the veneer wall to the structural backing without any risk of veneer disengagement.

For Poured Concrete

Holed Rap Tie

The functionality of the Holed Rap Tie is to transfer lateral load from the exterior masonry veneer to the structural backing with the use of one fastener. By using multiple fasteners, both shear and axial forces can be resisted, and this enables the entire wall assembly to function as a whole. The wall thickness (including the veneer and structural backing) work to limit lateral load, offering reduced lateral deflections and increased resistance.

Heavy Duty Holed Rap Tie

The functionality of the Heavy Duty Holed Rap Tie is to transfer lateral load from the exterior masonry veneer to the structural backing with the use of one fastener. By using multiple fasteners, both shear and axial forces can be resisted, and this enables the entire wall assembly to function as a whole. The wall thickness (including the veneer and structural backing) work to limit lateral load, offering reduced lateral deflections and increased resistance.

For Rubble Masonry

Rubble Stone Support

The Rubble Stone Support introduces a slotted extension strip onto either the Block Shear™ or Rap-Tie system, the V-Tie™ placement can be adjusted vertically to accommodate veneer materials with multi-dimensional properties. The Rubble Stone Support affixes rubble stone veneer walls to a structural backing like concrete block masonry.

The Rubble Stone Support transfers loads that are perpendicular to a wall, but they are not designed to resist parallel forces.

The holed Plate is mortared directly into a head joint in the structural backing. This creates a stable integration and it reduces any play, deflection or connector deterioration. The Support is mechanically fastened to two or more Plates and the V-Tie is inserted into the corresponding slot in the Support, providing a constant connection of the veneer wall to the structural backing without any risk of veneer disengagement.

For Thin Stone

Thin Stone Veneer Support

Our Thin Stone Veneer Support connects thin stone veneer walls to a structural backing either directly, or through any sheathing sitting over the stud.

The Thin Stone Veneer Support transfers lateral loads to the structural backing. The L-shaped, Plate is fastened to the surface of the structural backing. An additional Plate fastens to the L-shaped Plate and the slot on the second plate allows for enhanced flexibility in fastening the assembly.

Miscellaneous Ties

CAT-Tie (Column Adjustable Tie)

Affixes exterior masonry veneer to a structural steel surface, withstanding high lateral loads. The CAT Tie is a heavy-duty system and the V-Tie wire provides a constant connection of the veneer wall to the structural backing without any risk of veneer disengagement. This connector transfers high lateral loads through the V-Tie and AB-Clip application. It allows for greater push-through and pullout capacity in wall assemblies.

PAC Tie (Plate Adjustable Connector)

Affixes exterior masonry veneer to a structural backing like wood or steel studs. This PAC Tie connector transfers tensile and compressive lateral loads through the V-Tie, AB-Clip and Backer Plate application. Additionally, the Backer Plate distributes any concentrations of load over a large area, reducing the risk of damage to wood surfaces or structural backings.

Lateral Clip Tie

In areas with high-seismic building codes, masonry veneer requires single-wire reinforcement to run through to the masonry ties, our Lateral Tie Clip is a system engineered to work with FERO Masonry Connectors. The Lateral Tie Clip allows for greater push-through and pullout capacity than other conventional ties and systems.

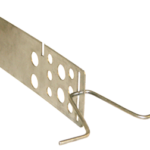

Prescriptive Corrugated Strip Tie

In addition to the wide selection of Engineered Ties, we also manufacture Prescriptive Ties/Anchors for wood frame structural backing applications. Our angled, corrugated product are a professional level alternative for designers and builders who need the reliability of engineered products that are standards compliant, products that out-perform the litany of non-compliant, non-professional grade masonry connectors currently in the marketplace.

These products are available in hot-dip galvanized finish or stainless steel.

Z-Bar

Z-Bar connects masonry walls to masonry walls and to other structural members, provides lateral support to the top of masonry walls, and resists wind and seismic forces acting normal to the wall

FERO Break-Away Fire-Release Connectors

Fero’s Break-Away™ Fire-Release Joist Connectors allow roof and floor collapse without compromising the firewall’s integrity. FERO has developed and patented our Break-Away Fire-Release Systems for connecting horizontal structural components, such as open web steel joists of floor and roof systems, to firewalls through the use of a fusible member, the connector allows for displacement, complete disengagement and collapse of the structural component from the wall during a fire before any significant damage could happen in the firewall itself, thereby satisfying the requirements of the National Building Code of Canada.

As a result firefighters have more time to prevent the spread of fire to adjacent spaces. In some cases, occupants in an adjacent room/structure would be provided with sufficient time to escape before the firewall is compromised and the fire spreads to the adjacent space.

Unlike other connectors currently on the market, our break-away connector uses a simple design that relies on only one part of the connector failing during the fire. This allows for disengagement of the structural component to occur only when required to prevent damage to the firewall, and not earlier. Other systems currently available on the market are made entirely from a fusible material.

Panel & Siding Components

Cladding Support

Our Cladding Support for Exterior Insulated Walls provides a rigid connection surface for cladding/siding while securing exterior insulation firmly in place no matter what the structural back-up wall system.

Panel Support

Our Panel Support for Exterior Insulated Walls provides a rigid connection surface for panelling while securing insulation firmly in place no matter what the structural back-up wall system.

Wood & Vinyl Siding Support

Implementing our Siding Support System creates a vented rainscreen channel between the building wrap and the siding material. With a drainage channel behind the siding – any wind driven or incidental water that penetrates the siding layer is easily drained by gravity or air vented through evaporation away from the building envelope.

The Siding Support is constructed from recycled plastic that creates a durable/rigid connection between the siding and the backing material.

The siding support is a direct replacement for wood furring strips, and is not susceptible to mildew, rot or decay like wood furring strips.

Fasteners

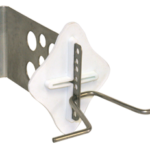

Insulation Supports

The Insulation Support is optional for all Fero Systems, but they have been designed to secure the sheet insulation in place. The Insulation Support is friction fitted over the exposed end of the Connector Plate and is itself locked in place by the V-Tie.

BENEFITS OF INSULATION SUPPORTS:

- Firmly restrains insulation against the air/vapour membrane

- Ensures proper performance of insulation

- Speeds up masonry construction