Mat dimensions can be customized to limit waste and increase installation efficiency, while the grid aperture can be reduced to accommodate smaller stone fill, decreasing mat thickness. Triton Gabion Mats can also serve as a lighter version of a marine mattress.riton Gabion Mats can also serve as a lighter version of a marine mattress.

Tensar

Tensar is a manufacturer of proven geosynthetic products and full provider of engineering services. Backed by extensive research and thoroughly tested, Tensar’s world-renowned geogrid products have set the industry standard. From major highways to heavy-duty haul roads, Tensar’s geogrid technology and asphalt reinforcement technology are proven solutions that decrease material costs, increase pavement life, and reduce maintenance and rehabilitation.

Tensar is the industry leader in soil stabilization and reinforcement. We have developed products and technologies that have been at the forefront of the geotechnical industry for the past three decades. Our products are backed by the most thorough quality assurance practices in the industry.

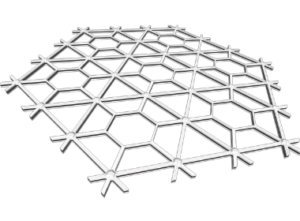

Tensar Geogrids

Tensar InterAx™ Geogrids

Tensar’s InterAx Geogrids are the most advanced geosynthetic made for trafficked surfaces and foundations. Ideal for subgrade stablilization, pavements, and working platforms. The optimized geometry for maximum confinement of granular fill creates the most efficient stabilized layer. Due to advanced material science to improve compaction and restrict movement over time, stiffness is retained long term which further enhances performance. InterAx geogrids are a more resilient solution that will withstand severe weather events, climate change impacts, and other challenging environmental conditions.

Tensar® TriAx® (TX) Geogrids

Tensar® TriAx® Geogrid is an advanced product specifically designed for trafficked surfaces. TriAx Geogrid’s multi-directional properties leverage triangular geometry, one of construction’s most stable and widely utilized shapes, to provide an enhanced level of in-plane stiffness. Its triangular structure, coupled with improved rib and junction geometry, offers the construction industry an improved alternative to conventional materials and practices.

TriAx TX130S Geogrid Product Specification Sheet

TriAx TX140 Geogrid Product Specification Sheet

Tensar® TriAx® FilterGrid™

Tensar® TriAx® Filtergrid™ is unique in the geosynthetic market. When stabilizing paved or unpaved structures it is important to not only consider the appropriate geogrid product and thickness of granular fill, but also whether adequate filtration and separation of dissimilar materials will be maintained throughout the life of the structure. Tensar TriAx FilterGrid provides the superior performance to Tensar’s patented TriAx technology along with the added assurance of a non-woven geotextile – all in a single composite product.

TriAx Geogrid Myth vs Fact

Even though Tensar Geogrid has undergone extensive, third-party testing and has been used globally for more than three decades, there are several misconceptions surrounding its application. Below we review the top seven myths and debunk them with facts.

Wind Farm Application

Tensar International offers state-of-the-art design solutions that can be used effectively in the wind farm industry for haul/access roads and working platforms. By incorporating Tensar TriAx Geogrids, a mechanically stabilized layer is created for the haul/access roads and working areas. Construction savings of up to 50% can be realized in the amount of aggregate required. This results in less excavated material needed to be taken away from the site, and less aggregate needed to be imported, placed and compacted.

Tensar Biaxial BX Geogrids

Tensar International invented and advanced the biaxial form of geogrid – the original geogrid. Tensar® BX Geogrids have been used for mechanical ground stabilization in over half a million projects worldwide, including roads, reinforced foundations and working platforms.

Tensar Uniaxial (UX) Geogrids

Tensar® Uniaxial (UX) Geogrids are manufactured from select grades of high-density polyethylene (HDPE) resins that are highly oriented and are designed to resist elongation (creep) when subjected to heavy loads for long periods of time. These geogrids are also highly resistant to installation damage as well as long-term chemical or biological degradation. In fact, Tensar UX Geogrids have shown no degradation in soils with pH levels measuring as high as 12 and can be used in both dry and wet environments. Given the inert properties of HDPE resins, they can be designed for use with a variety of backfill materials, including on-site soils and recycled concrete.

Tensar Retaining Wall & Slope Retention Systems

ARES® Retaining Wall Systems

From the ground up, everything about ARES® Retaining Wall Systems has been designed to resist chemical, biological or electrical corrosion. Like all of our mechanically stabilized earth (MSE) systems, ARES Systems feature integrated components developed to work together for optimum efficiency, top performance and ease of installation.

One Solution, Two Construction Options – ARES Systems offer two primary construction options depending upon your site, structural, and budgetary needs: panel walls and two-stage construction walls.

SierraScape® Retaining Wall System

A lower cost alternative to cast-in-place and other concrete retaining walls, the SierraScape® Wire-Formed Retaining Wall System is the superior choice for appearance, performance and value. Welded wire forms, Tensar® Geogrids and a locking tail strut connecting the two work together to resist differential settlement, seismic activity and heavy external loads. Inert to chemical degradation, the high-density polyethylene (HDPE) geogrids enable a wider variety of fill materials to be used, including on-site soils and recycled concrete.

SierraScape Installation Guide

Tensar SierraScape Installation Video

Sierra® Slope Retention System

The Sierra® Slope Retention System provides an economic and aesthetic alternative to conventional concrete retaining walls, replacing them with natural, landscaped, sloping structures nearly indistinguishable from native terrain. These graded and steepened reinforced soil slopes (RSS) typically range from 26° to 70° from horizontal, depending upon site development conditions. Unlike flatter slopes, Sierra Slope Systems claim a smaller footprint as they maximize developable land, create usable land in undeveloped areas and enhance property values.

Sierra Slopes can be installed in the most challenging grade separation projects. Varying curves and face angles can be created for a more natural look, and a number of facing options, including plantable sod, hydroseeding, native vegetation and bioengineering, can be specified. Like all Tensar systems, the Sierra System is installed quickly and without specialized equipment or labor.

Triton® Systems

Triton® Marine Mattress System

Composed of a Tensar® Geogrid structure filled with stone, the Triton® Marine Mattress System was developed for erosion control and submerged foundation applications, including:

- Shoreline revetments and dune stabilization

- Foundations for breakwaters, jetties, groins and dikes

- Pipeline cover to prevent scour and protect submerged pipelines

- Scour mats for underwater pipeline crossings and sewage outfalls

- Riverbank protection, channel lining and bridge scour abatement

Triton® Gabions and Triton® Gabion Mats

Triton® Gabions and Triton® Gabion Mats offer a durable, non-corrosive and installation-friendly alternative to conventional steel wire gabions, including galvanized and PVC-coated gabions. Constructed with Tensar® Geogrid, Triton® Gabions and Gabion Mats are available in prefabricated units or in standard roll form. Triton Gabions and Gabion Mats are specified for use where there is high potential for corrosion, including:

- Salt water environments

- De-icing salt/chemical runoff

- Acidic environments in mining operations

Triton® Grid Composite System

Grid composites provide an improved foundation and filtration layer for a wide range of conventional construction alternatives such as riprap, rubble-mound structures and similar installations. Designed for use beneath riprap and armor stone, the Triton® Grid Composite System combines durable Tensar® Geogrid with geotextiles. While geotextiles offer separation and filtration at the subgrade interface, Tensar Geogrid enhances performance by:

- Reducing settlement by distributing loads over a wider area

- Securing the geotextile firmly against the subgrade to mitigate scour

- Providing a protective “cushion” for the geotextile during and after installation

The Triton Grid Composite System is particularly effective for improving performance and constructability in difficult conditions including:

- Underwater construction

- Construction over soft subgrade soils

- Sand tightening of existing rock structures

Triton® Filter Mattress System

The Triton® Filter Mattress System was developed to address challenging underwater installations, providing a method to deploy, place and secure geotextile fabric in deep water and/or strong currents. A Triton Filter Mattress features a geotextile fabric encapsulated within or attached to the bottom of a stone-filled mattress made of Tensar® Geogrid. The stone fill provides ballast weight for the fabric as well as a bedding layer for additional riprap or armor stone.

Triton Filter Mattresses are also used for in situ capping of contaminated sediment. In addition to erosion control, Triton Filter Mattresses address industry concerns regarding:

- Potential for re-suspension of contaminants

- Erodibility of capping material

- Constructability, including uniform cap thickness and over-design of the capping layer to compensate for loss during construction

- Maintenance concerns, including cost and accessibility

- Overall durability of capping materials

Triton® Marine Cells

Triton® Marine Cells are used to construct high-strength, composite earth fills in adverse conditions including confined, structural-quality fills built below the water level or with weak fill materials (a geotextile liner placed within the cells enables the use of fine-grained fill materials).

Applications include:

- Bulkheads (new construction or rehabilitation)

- Cores for breakwaters, groins, jetties and dikes

- Foundations for embankments or mechanically stabilized earth (MSE) slopes or walls

- Containment dikes for dredge spoils or other waste materials

Glasgrid Systems

GlasGrid® Asphalt Reinforcement System

The GlasGrid® Asphalt Reinforcement System is composed of fiberglass strands coated with an elastomeric polymer and formed into a grid structure. Each strand has a remarkably high tensile strength and high modulus of elasticity; this is particularly important as asphalt concrete typically cracks at low strains.

When the GlasGrid System is sandwiched between the leveling course and the surface course in an asphalt overlay, it becomes the hidden strength in the road, turning vertical crack stresses horizontally to effectively dissipate them.

Easily Installed, Durable in Any Climate – With its pressure-activated adhesive coating on the underside, it’s also one of the fastest interlayer systems installed; up to 25,000 square yards of grid can be placed in one day with a standard laydown unit.

For road construction projects that require a moisture barrier, Tensar offers the GlasGrid® CG (Compogrid) System. Incorporating a lightweight, polypropylene fabric on the back of the main grid component, GlasGrid CG provides additional pavement protection on both new construction and pavement rehabilitation projects.

GlasGrid® TF

The GlasGrid® TF (Tack Film) System provides all the benefits of GlasGrid product, but without the challenges of having to apply a conventional tack coat. With a pre-installed layer of polymer tack film, GlasGrid TF performs like the original GlasGrid System, protecting against reflective cracking while it bonds to asphalt overlays.

Convenient installation is just one of its many benefits. Laboratory beam testing indicates that GlasGrid TF delivers five times the fatigue performance of an unreinforced asphalt section, resulting in longer life for asphalt overlays. With no tack coat emulsion to prepare and apply, owners and installers save on time, labor and material costs, increasing productivity. The elimination of a conventional tack coat also reduces VOC emissions from construction.